3 Ways to Convert Your Winches to Self-Tailing

Self-tailing winches are a great upgrade - but expensive. Luckily, there are a couple of budget ways to create your own self-tailing winches.

How to convert your winches to self-tailing? There are three ways to do it. The simplest and most cost-effective way to convert your winches is by installing 'winchers'. These are simple rubbers that hold the rope for you. You could also use a winch conversion kit like Winchmate. Or you could replace the winches by self-tailing ones.

I prefer the first option. The winchers are easy to install. But make sure you get the right size because otherwise it won't work and the installation can get frustrating. The conversion kit is also a solid way to do it if you have the cash. The last option is A LOT more expensive, and I don't think it's worth the investment.

Different Ways to Get Self-Tailing Winches

What is a Self-Tailing Winch? Winches are used to haul in the lines. A self-tailing winch holds the line in place for you. This way, you don't have to hold the line when you're turning the winch. You also don't need an extra pair of hands for pulling the line. So self-tailing winches are the perfect solution for solo sailors.

A regular self-tailing winch has a feeder arm which 'feeds' the line to the top of the winch. The top drum has a sort of jaw. The line goes into the jaw, which holds the line for you.

There are basically three ways to convert your winches.

- Barton winchers (click to check the price on Amazon) - this is your best buy and budget option

- Winchmate conversion kit (click to check their website) - I really like this product, but it's a bit more expensive

- winch replacement (click to check the price on Amazon) - this isn't really an option for me (too expensive)

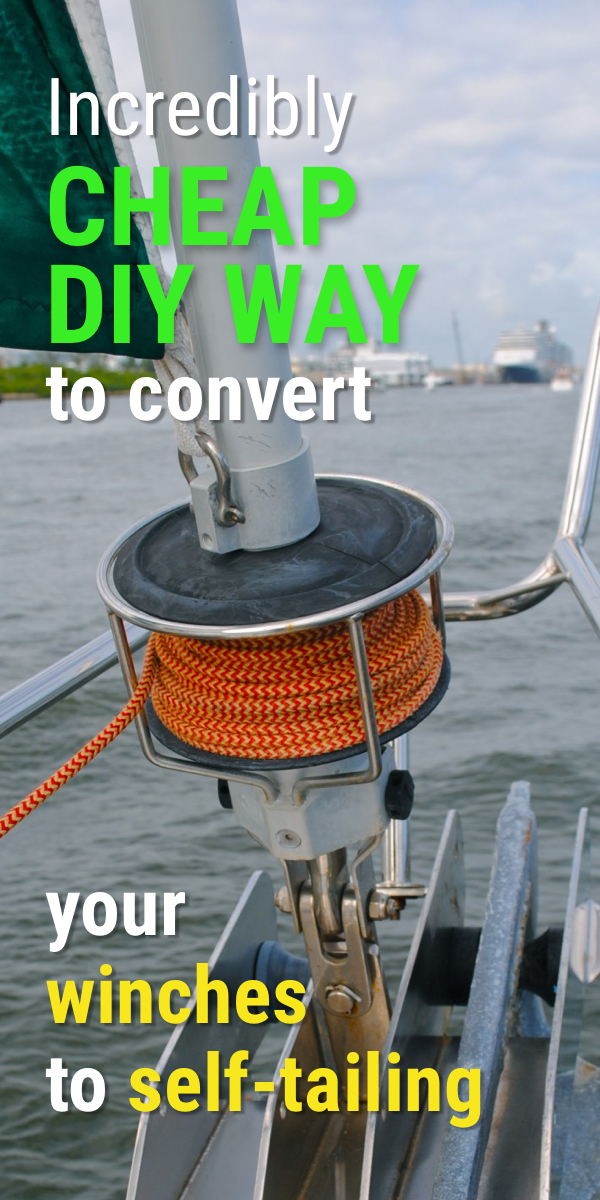

Winchers are simple rubber conversion rings. You install them on your current winches, which means you don't have to do an expensive replacement. They're inexpensive. Installation can be a bit of a pain but shouldn't be too difficult. I'll explain more on this option and how to install them later on.

The Winchmate conversion kit can help you to properly convert your winches. This kit includes an entire new top drum, including the feeding arm. Converting your winch this way creates a true self-tailing winch, ensuring you are in control of your lines.

Replacement is the best way to get self-tailing winches, but also the most expensive. I think you didn't come here looking for the obvious, so I'll leave it at that. If you want to have a cheap alternative, read on.

Why I Chose for Barton Marine's Winchers

I like the Barton Marine winchers the most because it's the simplest and most universal way of converting. Their winchers fit most winches. It's the KISS (sweet and simple) method. I always go for the KISS way.

It's the cheapest by far and works well enough for me (I'm not doing any ocean passages any time soon).

However, if you want a lifetime solution, check out Winchmate. Their conversion kits are pretty neat as well. You get the entire top part of the winch, so installation is a piece of cake. I guess this is also a good option. Tech specs are better than rubber winchers:

- has a line lifter/feeder arm

- aluminum line jaws instead of rubber

- installation is (if possible) even easier - 20 - 30 minutes

- you get a true self-tailing winch

The only disadvantage I can think of is that the investment doesn't get you a new winch, which means the Winchmate will only last you as long as your winch.

Pros and Cons of Barton Winchers

There are a couple of things to consider here. First, let's take a look at the pros:

Pros

- It's cheap - a pair of winchers probably cost under a $100 (for both sides). A pair of new self-tailing winches (A-brand) will cost you about 20-30 times that amount!

- The conversion is pretty easy to do

- They work fine

- They last you long enough - roughly about at least 5-10 years

If you're thinking: how will a rubber disc ever hold up? They hold up just fine. I've even read some accounts of a 12-ton sloop that uses these, and mid-sized yachts with heavy sails. All without any trouble whatsoever.

Cons

The biggest disadvantage is that the entire winch must be stacked with line for self-tailing to work. The wincher grips the line with the rubber underside of the wincher. So if the line doesn't reach all the way up to the underside of the wincher, it doesn't work. In practice, this doesn't cause trouble.

Winches don't have a feeder arm which controls the line. So it's a bit less secure, and you have to make sure the rubber jaw grips the line properly. But in my opinion, this isn't a real problem. I don't know of anybody that had a problem with the jaws not holding the line.

I've heard of someone that had a problem with the fit of the wincher - it slipped on the winch. But for most people they fit just fine and don't slip at all - even with larger winches. I suggest dry fitting the rubbers before actually installing them - you can always return them and get a more expensive solution.

How To Get the Right Size

The Barton Marine winchers fit standard-sized winches - so most, but not all.

They come in four universal sizes: small, medium, large, and x-large.

To get the right size, check the technical specs of your winch and look for the drum diameter. Then, choose the right wincher size from the table below:

| Wincher size | max. Ø drum (mm) | max. Ø rope (mm) |

|---|---|---|

| small | 64-70 | 8-10 |

| medium | 70-80 | 10-14 |

| large | 80-90 | 12-14 |

| x-large | 90-100 | 12-16 |

This info comes directly from the Barton Marine website.

The larger the drum diameter for that particular size, the tighter it will be. Which is a nuisance for installation, and a good thing for the grip.

How to Install

For installation, you need a flat-headed screwdriver and a Philips screwdriver.

- Soak the wincher in hot water with washing up soap. This softens them up. You have to be able to stretch them just enough to put them over the top of the winch.

- Undo the top disc of the winch, and remove the screws. Then, take off the entire top drum.

- Slide over the wincher. It can be an incredibly tight fit. Like all rubber parts, you'll probably wonder whether you've ordered the right size. But hey, the tighter it is now, the firmer it will stay in place later.

- Replace the top drum. Then, flip the top rubber edge over the top of the drum by running a screwdriver around the edge (a bit like placing a bicycle tire).

If you are more of a visual person, here's a good video that shows you how it's done. The audio is a bit windy but it gets better later on.

Related Questions

What does a self-tailing winch do? A self-tailing winch holds the line in place by itself. This means you don't need to hold the line while you're turning the winch, or need an extra pair of hands for pulling the line. Because of this, a self-tailing winch allows you to sail short-handed (solo).

What's the top groove on a wincher for? The top groove on a rubber wincher is called the jaw, and it's simply used to cleat the line. You don't need to use it when you're hauling in line. You may also use your original cleats. However, some people find it handy to use this rubber cleat on top of the winch.

Did you find the answer to your specific question?

👍 16 👎 0

Comments

Lars Dahlberg

As you live in The Netherlands, did you ever see a solution for the Dutch Enkes winches?

Sailing Infidels

Barton Winchers are not a self-tailing upgrade. There are no self-tailing arms. They are line cleats for your winches.

Leave a comment